양주 증류공정을 위한 품질관리

장기간의 유효기간 동안 부드러운 맛을 보존할 수 있는 싸토리우스의 품질관리 솔루션

양주의 경우 알코올 함량이 높기 때문에 미생물 오염에 대한 우려가 상대적으로 적지만, 에탄올의 미생물 억제 기능이 저하되는 등의 이유로 공정상 오염이 개입할 수 있는 소지가 충분히 존재합니다. 원료 투입, 제조, 병입 등 생산공정의 각 지점에서 일상 테스트를 철저하게 시행하면 공정 상 오염을 방지할 수 있습니다.

양주 제조공정에서도, 역시 싸토리우스의 품질관리(QC) 솔루션을 사용하여 일상 테스트를 손쉽게 관리하실 수 있습니다.

고객사의 QC 공정에 부합하는 싸토리우스 솔루션

You are committed to creating high-quality spirits with consistent look, smell, feel and flavor from one bottle to the next. We are committed to providing you the products you need to ensure your spirits’ taste, aroma and quality. For spirits processing QC, we have solutions for the following applications:

Moisture Determination of Raw Materials and Spent Grain

To ensure the consistency and quality of your spirits, you need to have confidence in the quality of your raw materials. To do this, you must prevent fungal contamination in your raw materials by checking their moisture content before you start fermentation and distillation.

Also, at the end of production, to recycle waste and get the most out of your by-products, you can sell your spent grain as livestock feed. Here, testing its moisture content is again critical to avoiding fungal contamination and making sure you get the best price for your spent grain.

시험 대상

- 원료 함수량 결정

- Moisture analysis on spent grains

Sartorius has products and solutions to help you detect moisture quickly and easily in your raw ingredients and spent grain.

MA 160 수분분석기

전통적인 드라이 오븐법 대비 신속한 분석 가능 Compact design for routine spirits production and incoming inspection. Ideal for deal for cereal graines, additives, sugar, solid process wastes and any organic sample.

- Easy sample handling, designed for a secure and fast sampling removal.

- Intuitive configuration and image-guided programs procedure.

- Large 4.3“ color display, including touch and scroll functionality. Dry programs procedure are image guided.

- Status light / acoustic signal shows status of analysis of the spirit process.

- Achieve reference value in three easy steps with Method Development Assistant.

- Better Clean Design - for easy organic removal from the heating areas.

- Safe storage of 100 programs for different samples and 9999 results, sorted by date.

MA 37 수분분석기

Rugged design, 100% reliable with low space requirements and easy operation for spirits production.

- Intuitive configuration and image guided programs procedure.

- Large 4.3“ color display, including touch and scroll functionality.

- Status light / Acoustic signal that shows the analysis status of the spirts process.

- Better Clean Design - for easy organic removal from the heating areas.

Water Testing

Although cities routinely perform microbiological and chemical water monitoring, contamination can occur in your distillery during the production process, so regular, weekly testing of water supplies and piping, tubing/gaskets is recommended.

Water is also added at the proofing stage of your spirit production to reduce the percentage alcohol or “proof” to a safe, drinkable level. The water quality you use for this application must be of a purity standard appropriate for drinking water, or there is a risk of "floc haze" appearing in the spirits during bottling due to chemical contaminants precipitating out or a microbial biofilm developing.

시험 대상

Regular total colony counts and tests to identify coliform bacteria and specifically E.coli are recommended for microbiological quality control of this important ingredient.

e.motion 디스펜서용 멤브레인 필터

Optimize microbiological water testing workflows and save time. Dispense filters automatically eliminating the need for manual operation. Benefits include for spirits production include:

- Easy colony counting due to clear colony morphology and distinct grid lines.

- High speed spirits sample filtration.

- Avoid re-loading during a shift with 250 filters per pack.

Microsart® e.motion Dispenser

Automatically dispense membrane filters for water testing by touch of a button, hands-free motion detection or a foot switch to minimize risk of secondary contamination. Benefits for spirits production include:

- Space-saving small footprint.

- Easy to clean, lightweight and robust.

- Available with long-life battery option.

Microsart® Manifold

Facilitate routine microbiological water testing of spirits by selecting the manifold size (1, 2 3 and 6 branch). Compatible with all Sartorius reusable and single use funnels and filtration units. Benefits for spirits production include:

- Robust, full stainless steel material.

- Easy assembly without tools.

- Easy to clean and operate.

Biosart® 100 모니터

Ready-to-use sterile filtration unit combines a 100 ml funnel, lid, filter base, gridded membrane filter and a cellulose pad in one unit. After filtration, simply add nutrient media and remove the funnel to convert the monitor into a petri dish, eliminating the need to manipulate the membrane. Benefits for spirits production include:

- All-in-one design saves time and handling steps.

- Minimize the risk of secondary contamination.

- Different ampoule media types available for water quality control of spirits.

Biosart® 100 영양물질 배지

Sterile ready-to-use liquid media in 2.5ml ampoules. For use with Biosart Monitors or Cellulose Pads in Petri dishes. Benefits for spirits production include:

- Eliminates time required to prepare media.

- Saves space in the laboratory refrigerator.

- Different ampoule media types available for water testing of spirits.

Microsart@filter

Ready-to-use sterile filtration unit in 100 or 250ml sizes. Combine a funnel, filter base and gridded membrane filter in one unit. Benefits for spirits production include:

- Reduces time and handling as autoclaving of funnels and base is eliminated.

- Available in different pore sizes and membrane colors.

- Reliable results as no liquid remains after filtration.

Nutrient Pad Sets (NPS)

As alternative to agar plates, NPS are dehydrated media pads in petri dishes, packed in a double layer aluminium protective bag. Available with membrane filters for economical, time-saving microbiological quality control of water. Benefits for spirits production include:

- Eliminate time-consuming, labor-intensive culture media preparation.

- Eliminates need to keep media pads cool during storage or transportation.

- Long, 2 year shelf-life.

- Different NPS media types available for water testing of spirits.

New Video: Nutrient Pad Sets: For Quality Control of Beer Samples

Spoilage Testing

Despite the anti‐microbial properties of spirits and having a Hazard Analysis and Critical Control Point system (HACCP) system in place, microbial contamination can occur before distillation and in your proofing water.

This can lead to the formation of floc or haze in your spirits, which can affect your shelf life stability and customer’s confidence in your brand.

시험 대상

- Total colony count testing of proofing water

Sartorius has the products and solutions for fast, effective, and efficient detection and capture of potential spoilage-producing microorganisms to maintain the quality of your spirits on the shelf.

e.motion 디스펜서용 멤브레인 필터

Optimize spoilage detection workflows and save time. Dispense filters automatically eliminating the need for manual operation. Benefits include for spirits production include:

- High speed spirit sample filtration.

- Easy colony counting due to clear colony morphology and distinct grid lines.

- Avoid re-loading during a shift with 250 filters per pack.

Microsart® e.motion Dispenser

Automatically dispense membrane filters for spoilage detection by touch of a button, hands-free motion detection or a foot switch to minimize risk of secondary contamination. Benefits for spirits production include:

- Space-saving small footprint.

- Easy to clean, lightweight and robust.

- Available with long-life battery option.

Microsart® Manifold

Facilitate routine spoilage detection of spirits by selecting the manifold size (1, 2 3 and 6 branch). Compatible with all Sartorius reusable and single use funnels and filtration unts. Benefits for spirits production include:

- Robust, full stainless steel material.

- Easy assembly without tools.

- Easy to clean and operate.

Biosart® 100 모니터

Ready-to-use sterile filtration unit combines a 100 ml funnel, lid, filter base, gridded membrane filter and a cellulose pad in one unit. After filtration, simply add nutrient media and remove the funnel to convert the monitor into a petri dish, eliminating the need to manipulate the membrane. Benefits for spirits production include:

- All-in-one design saves time and handling steps.

- Minimize the risk of secondary contamination.

- Different ampoule media types available for microbiological quality control of spirits.

Biosart® 100 영양물질 배지

Sterile ready-to-use liquid media in 2.5ml ampoules. For use with Biosart Monitors or Cellulose Pads in Petri dishes. Benefits for spirits production include:

- Eliminates time required to prepare media.

- Saves space in the laboratory refrigerator.

- Different ampoule media types available for spoilage detection of spirits.

Microsart@filter

Ready-to-use sterile filtration unit in 100 or 250ml sizes. Combine a funnel, filter base and gridded membrane filter in one unit. Benefits for spirits production include:

- Reduces time and handling as autoclaving of funnels and base is eliminated.

- Available in different pore sizes and membrane colors.

- Reliable results as no liquid remains after filtration.

Nutrient Pad Sets (NPS)

As alternative to agar plates, NPS are dehydrated media pads in petri dishes, packed in a double layer aluminum protective bag. Available with membrane filters for economical, time-saving spoilage detection. Benefits for spirits production include:

- Eliminate time-consuming, labor-intensive culture media preparation.

- Eliminates need to keep media pads cool during storage or transportation.

- Long, 2 year shelf-life.

- Different NPS media types available for microbiological quality control of spirits.

New Video: Nutrient Pad Sets: For Quality Control of Beer Samples

Analytical QC

If your spirits age in wooden barrels, they acquire tannins, sugars, complex biochemical compounds and color, as well as undergo significant chemical reactions. The profile of your spirits are modified in ways that are complex and analytical sample testing can be used to detect or follow changes as your spirits age. Based on blending, process, aging and additives, you can characterize distinct fingerprints both within the same type of spirit and detect differences in your brand. Eventually, it is possible to generate a product fingerprint library that you can use to help maintain product quality and detect adulteration of your spirits to ensure it meets your customer’s high standards.

These tests can detect the following:

- Sugar content, nitrogen compounds, salts and minerals, and other compounds that may be present

- Alcohol content

- Measurement of pH value

- Compounds such as international bitterness units (IBUs), polyphenols, free amino nitrogen, sulfur dioxide

- Ash content before distillation (in rum only)

- Color measurements

- Overall "proof" or alcohol concentration after distillation using a hygrometer

- Alcohol content using a pycnometer or dry matter determination of residue on ignition

To run any analytical or sensory tests, you need the right tools for sample preparation, such as pipettes, laboratory balances, syringe filters, filter papers and water purification systems. The quality of your results is dependent on the quality of your sample, and at Sartorius we provide the right products and solutions to make your sample preparation for analytical testing quick, accurate and efficient.

Arium® Mini UV Water Filtration System

Quality control of spirits is essential for consumer safety. The water used for highly sensitive chromatographic analysis such as HPLC, GC-MS, or ICP must always be high quality. Arium® Mini lab water system is a compact ultrapure water system for labs with requirements up to 15 liters per day. The option UV lamp (185/254 nm) removes TOC levels down to < 5 ppb. Key advantages:

- Consistent delivery of high quality ASTM Type 1 water increases sensitivity of analytical results and minimizes chemical ion interference.

- Comprehensive services include installation and preventative maintenance for consistent and reliable water quality.

Filter papers

Many analytical QC tests in brewery labs require a filtration step prior to the testing procedure to pre-process the sample. Circular, pleated filter papers of different grades are placed into a funnel leading to a receptacle and are used to remove turbidity from wort, to remove yeast cells after fermentation and to reduce CO² or degas the sample prior to tests such as density measurement or specific gravity.

The filter papers fitting best into your beer process are these types:

- Filter paper grade 292a : FT-4-215-320

- Filter paper grade 1289: FT-4-207-320

- Filter paper grade 6: FT-4-312-320

- Filter paper grade 4b: FT-4-309-320

Cubis®️ II Premium Laboratory Balance

Precision Balances offer the highest performance for spriit producers. Fully configurable hardware and software ensure connectivity, compliance and confidence in results.

- Avoid sampling errors with the largest 7“ color display with touch, scroll and swipe functionalities; graphic guided procedures/applications are built-in and dozens of QApp Packages are available including statistics, averaging, check weighing with counter and 70 others.

- Status Center provides system info, notifications, tasks, and alerts. Advanced user management includes centralized password support, high security configuration and login rules with LDAP capabilities.

- Unique, built-in, interactive motorized auto-levelling function up to 8 kg.

- Easy to clean rounded edges and chemical resistance.

Quintix® Lab Balance

Unsurpassed weighing technology for beverage producers available in Analytical and Precision Balances.

- Optimzed performance directly out-of-the-box with Start Assistant, SmartTouch and intuitive applications.

- Built-in applications include statistics, totalizing, mixing and density determination; menu lock function available to avoid configuration changes.

- Easy to clean rounded edges and chemical resistance to eliminate residues or spill stains.

Prospenser and Prospenser Plus

Robust design and high-quality materials provide accurate and precise dispensing during spirits production.

- Lightweight and easy to use

- Excellent chemical resistance and fully autoclavable

Tacta® Pipette

- Superb comfort and unparallled reliability ensures minimal variation for spirits producers.

- Advanced ergonomics including soft tip attachment and light ejection delivers the best user experience.

- Adjustable to improve pipetting accuracy by accommodating for viscosity or liquid temperature .

- With only three parts to clean, there is a low risk of contamination. Combine with Safe-Cone filters or SafetySpace Filter tips to further increase contamination control and prolong pipette lifetime.

Optifit 팁

- With a perfect fit and seal, Sartorius pipettes deliver the highest possible accuracy and precision for spirits producers. Further improve pipetting performance of viscous liquids with low retention tips.

- Broad volume range and packaging options to suit your application and use.

- Optifit tips meet the highest purity and quality standards.

Minisart® 시린지 필터

- Samples for HPLC, GC-MS, or ICP require proper clarification prior analysis to ensure high sensitivity and accuracy and protect instruments from particle load during spirits production.

- Minisart® syringe filters are optimized for sample preparation with maximum chemical compatibility to ensure high performance. Minisart® RC is optimized for aqueous liquids, solvents and a wide range of chemicals.

- Minisart® NY Plus syringe filters include a pure quartz glass fiber prefilter optimized for sample prep of particle-laden samples prior to HPLC or GC . The polyamide membrane combines fastest flow with low non-specific binding.

- Minisart® SRP filters are suitable for venting applications and leachable-free clarification for liquids in a pH range of 1 -14. Minisart® PES offers a combination of PES membrane and PP housing and has a higher chemical compatibility than PES in MBS housing.

Claristep®

- Samples for HPLC, GC-MS and ICP require proper clarification prior analysis, however, to ensure high sensitivity and accuracy and protect instruments from particle load during spirits production.

- The Claristep® Filtration System can process up to eight samples simultaneously without any vacuum source or power supply. The syringeless filter and the simple manual processing enable customers to simplify their sample clarification.

Check Weighing

Accurately determining if your bottles are over or unfilled with spirits, is a critical step in ensuring product quality and maintaining your brand’s reputation with customers.

Our balances provide a reliable method of checking the weight of filled bottles of spirits. Their height supports easy handling of glass bottles and using the Check Weighing program with defined limits and weighing visual aids means that with minimal training your staff can control the weight of filled bottles or nominal gross weights more accurately and cost-effectively than you would using balance technology built into your production line.

Featuring, corrosion resistant stainless-steel weighing pans and simple easy clean, assemble/disassemble components our balances are ideally suited for use in production facilities where you are weighing corrosive or sweet spirits and need to clean regularly. Where vibrations, airflow and temperature changes are challenging in your production area, our quick balance levelling technology, (bubble indicator on Entris® and Quintix® or simply press a button on Cubis® II balances) offers rapid stabilization times, maintaining accurate weighing performance time after time.

장비의 특성

- Check weight is a function in our essential weighing applications package that comes with Cubis® II (MCA), Quintix and Entris® II balances.

- Check weight determines whether a bottle weight falls within a specified tolerance range.

- Print out each measure and change to the next identical bottle or can and get the stats in the end at the touch of a button.

- Weighs safe the different bottle types (glass and plastic) in sizes from 0.3 L up to 5 L

Recommendations, norms, regulations and directives our balances work according to, include:

OIML R 79, R 87 & R138

Directives 76/211/EEC, 2007/45/EC, 2009/34/EC & 75/107/EEC

NIST Handbook 133, 21-C.F.R. Part 101 and 27-CFR Parts 5, 19 & 27

Cubis®️ II Premium Laboratory Balance

Precision Balances offer the highest performance for spirit producers. Fully configurable hardware and software ensure connectivity, compliance and confidence in results.

- Avoid sampling errors with the largest 7“ color display with touch, scroll and swipe functionalities; graphic guided procedures/applications are built-in and dozens of QApp Packages are available including statistics, averaging, check weighing with counter and 70 others.

- Status Center provides system info, notifications, tasks, and alerts. Advanced user management includes centralized password support, high security configuration and login rules with LDAP capabilities.

- Unique interactive, motorized auto-levelling function up to 8 kg or graphic-interactive guide up to 70 kg. Configurable electronic stabilization filters and lecture speeds for fast response in production areas.

- Easy to clean rounded edges and chemical resistance to eliminate organic residues or spill stains.

Quintix® Lab Balance

Featuring the highest performing weighing technology available in Precision Balances for spirit producers.

- Best performance right-out-of-the-box by its Start Assistant, SmartTouch and intuitive applications.

- Checkweighing, statistics and peak-hold built-in applications; menu lock function available to avoid configuration changes.

- Easy to clean and high chemical resistance disposable cover to avoid organic residues or spill stains.

Entris® II Lab Balance

Unrivalled value and performance in Precision Balances for spirit producers backed by 150 years of German engineering expertise.

- The only Balance in its class with an automatic internal calibration program, 4.3“ color touchscreen or LED touch display and built-in checkweighing application.

- Easy to clean and high chemical resistance polybutylene terephthalate (PBT), stainless steel and glass construction to avoid organic residues or spill stains.

Click here to go back to other applications

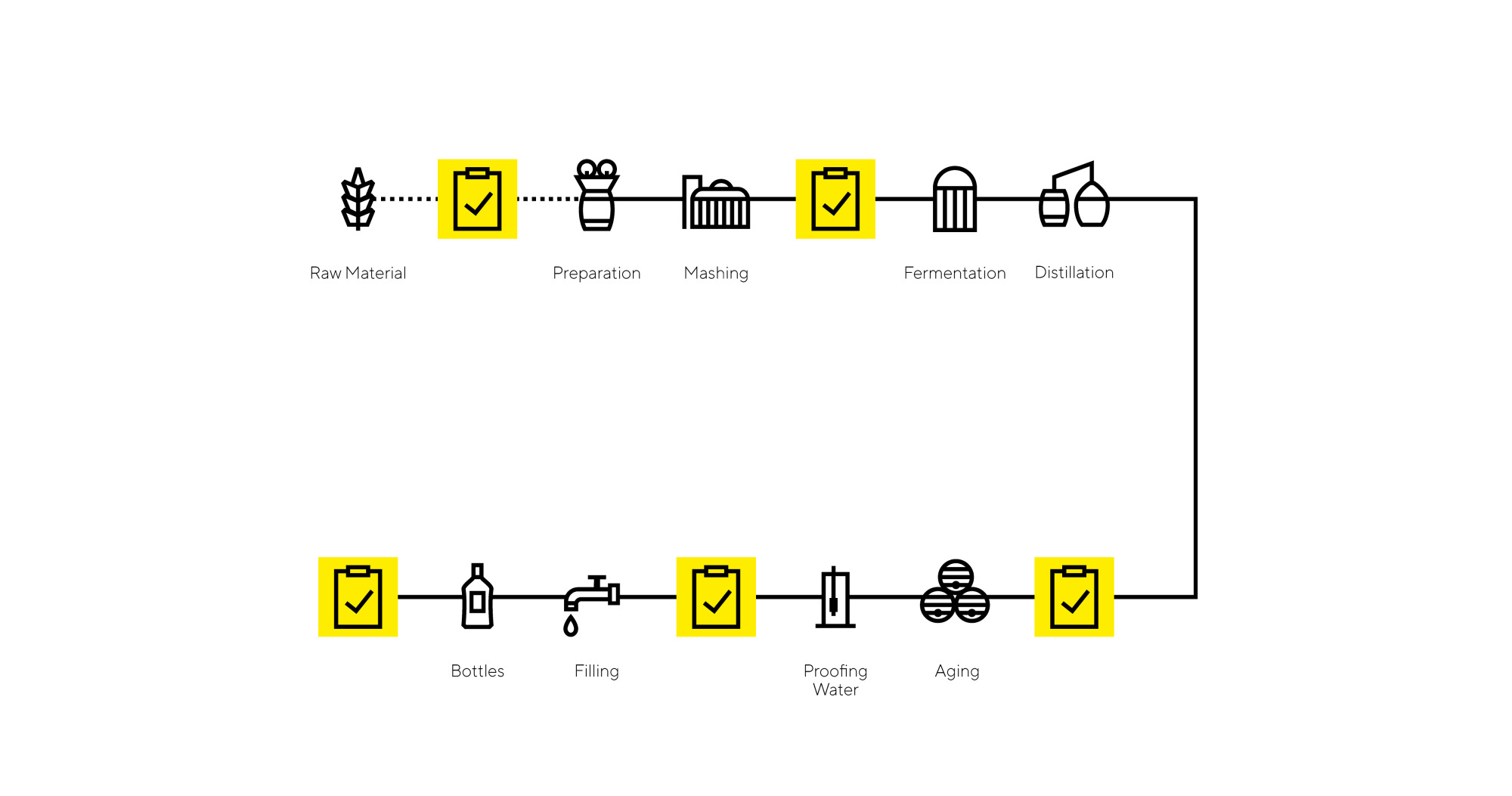

Process Flow Chart for Your Spirit Process*

Discover the different steps in the spirits workflow and click on the icon „+“ to get to know the variety of applications and solutions Sartorius offers for testing during your manufacturing process.

*This workflow may not exactly represent your spirits workflow however generalizes the QC checkpoints